MESSEN Check Valves

Check valves are generally installed in pipelines to prevent backflow. A check valve is a one-way valve, in which the flow runs freely. But, if the flow turns, the valve will close and thus protects the piping and other instruments in the control loop.

Why Messen Valves?

Our products are highly reliable with top-notch design and production process along effective sealing. Messen’s experienced engineering team is well equipped to cater to the needs of all special requirements of our valuable customers, thus empowering us to be a market leader in special applications of valve requirements.

Major Advantages

- Easy maintenance

- Carefully machined sealing surfaces

- Longer operating life

- Lower maintenance costs

- • Improved gland packing arrangement

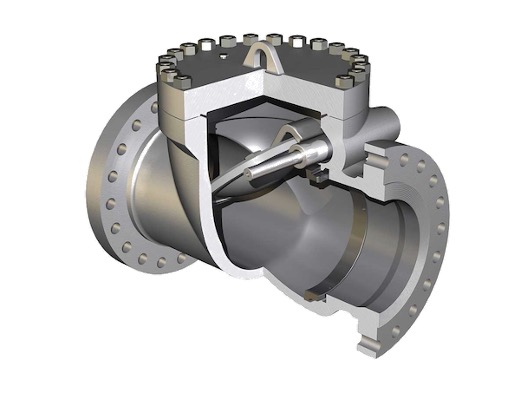

Swing Check Valve

The swing check valve consists of a valve body, seat, and disc linked to the axis. Upon encountering a specified flow rate thus achieving inlet pressure enough to push the disc to the horizontal position, enabling forward flow. Disc returns to the valve seat when the flow and the pressure drops to prevent backflow.

Dual Plate Check Valve

The Dual Plate Check Valve is equipped with two-spring-loaded plates hinged on a central shaft. When the flow rate decreases below the spring pressure, the plate closes thus preventing the back flow. This design offers twin advantages of reducing Water Hammer effect and non-Slam effect.